Leading the discussion in your business process transformation

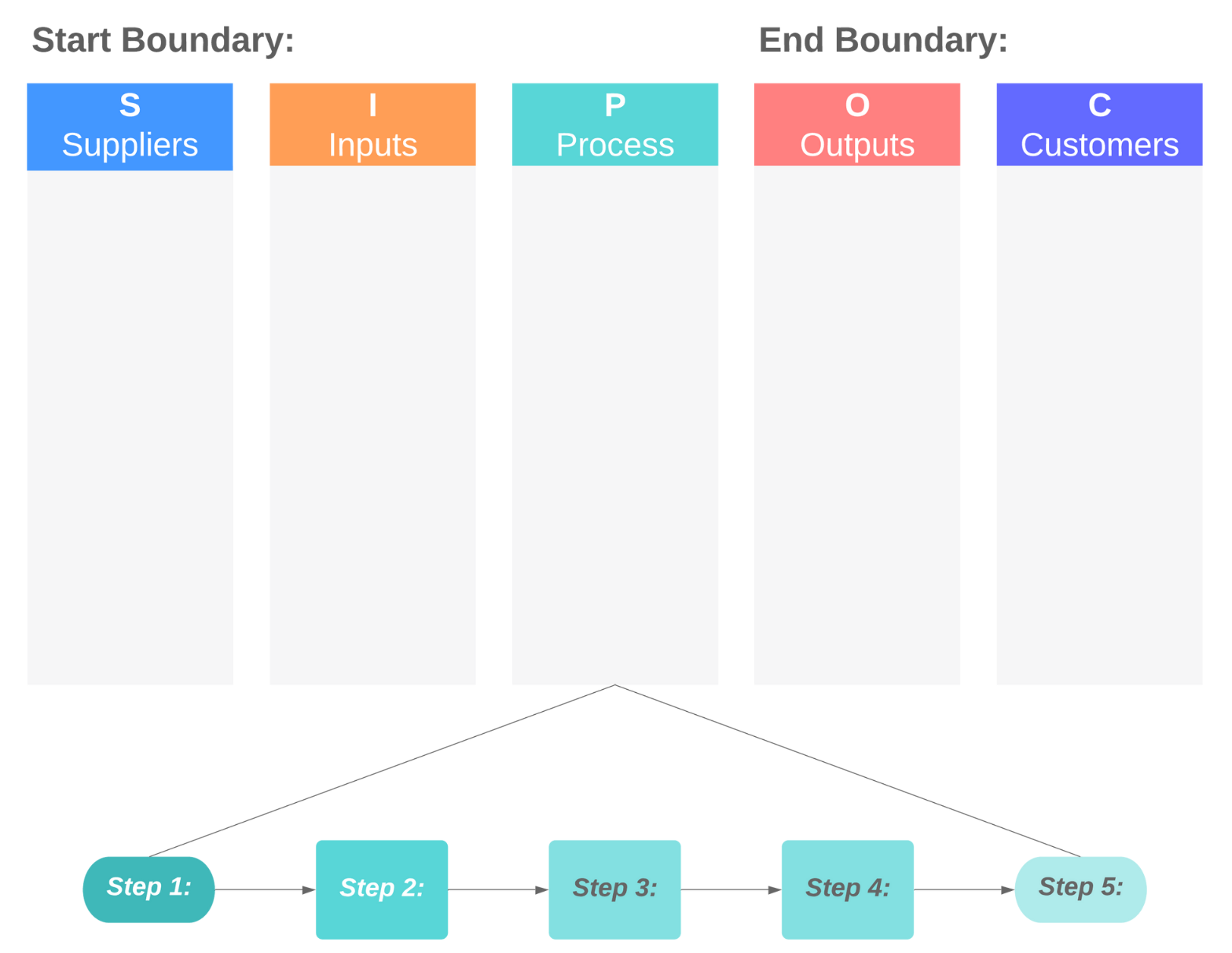

One of the first things to acknowledge when conducting a SIPOC is that it will paint a defined picture of your overarching process.

SIPOC stands for: suppliers – inputs – process – outputs – customers

A SIPOC will help you to visualise the nature and scope of your processes

It’s very simple to construct, has clear boundaries and is very high level. A SIPOC helps you to identify customers, process outputs, process inputs and suppliers. Conducting a SIPOC is just one of many tools which exist when implementing a program of change within a business, but its strength lies in the fact that it is scalable and brief- major benefits to conducting the exercise for the team.

A little insight

In a process, suppliers provide inputs and then inputs are used in the process to provide outputs that a customer requires. The process’ defined sequence usually consists of 4-6 major steps. The outputs are the products and the services or the information that is valuable to customers. The customer is the user of the outputs.

It’s as simple as that.

The benefits

There are some really interesting things that can be done with a SIPOC; it can be the precursor to all sorts of high-level discussion about a business transformation. It will help teams of people who work in different departments align their thinking about a process that’s common to them. Another advantage of a SIPOC is that if you are looking at an internal process you can very often get your suppliers, customers and the people conducting the process all in one room and have them agree within a very short period of time as to exactly what happens in that process.

Let’s talk

Quite often what happens when it comes to the work we have inside a business or even external to the business, our suppliers and our customers don’t actually know what each other creates or does. But within a business one of the really interesting things is that we have the same problems. For example, the sales team that supplies information to the operations team may not understand what the customers need exactly- they don’t understand what the process completed by operations needs to work effectively. The cool thing about a SIPOC is that it helps frame a lot of direction and discussion when it comes to business improvement at a high level.

You can use the SIPOC to zoom into a major opportunity to cash value stream. Then within that value stream, there are areas where you can get different departments of the business together and do a SIPOC together. Suddenly you’re communicating in the same language in the same way, at many levels. It’s very powerful.

The flow on effect

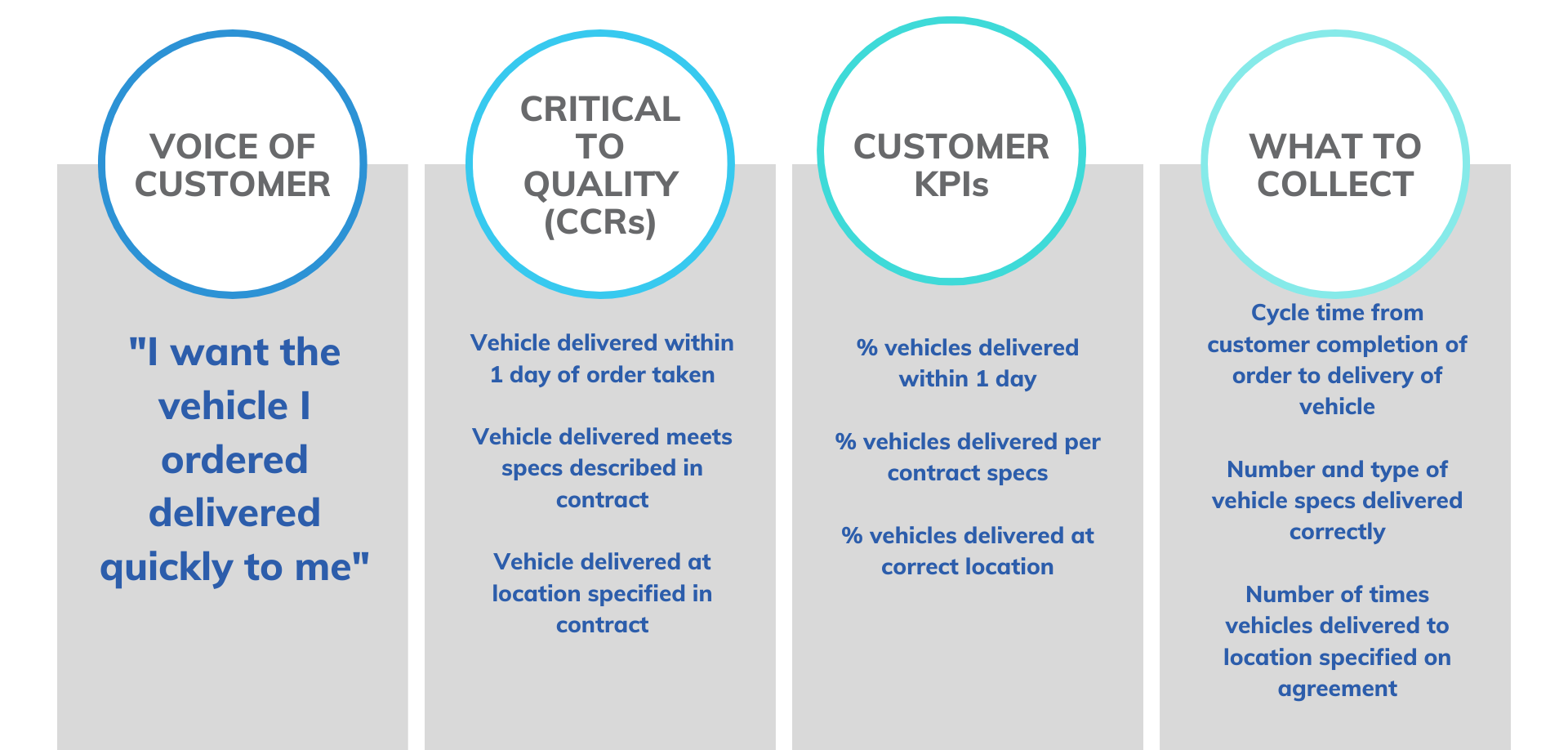

The other thing that is really cool about a SIPOC is that you can develop KPIs quite early on with great relevance to the process.

If you have a process on which you are conducting a SIPOC and you’ve got the supplier to that process in the room, you can start to look at the input KPIs, because obviously, they help the inputs. If we know what our critical requirements are of our supplier’s products and services or information, then we can identify and apply input indicators to measure those elements- indicators that affect our process in meeting our critical customer’s requirements.

Input indicators are true predictors of how things are going to pan out in a process. If a KPI shows us there is missing information, or they are being too slow on providing some kind of critical information to the process; there is a fair chance your process is going to fail. Good leading indicators from these inputs can help us to ensure that the process will run within tolerance and won’t have defects or excessive cycle time.

KPIs that can be developed from the process part of a SIPOC help us to predict our outputs- measure our quality or ability to deliver on time. They, of course, have a very strong relationship to the outputs.

Finally, I’ll talk about output KPIs. These are the things that the customer is focused on, and the customer could be internal or external- there is no hard and fast rule there. The interesting thing about KPIs in the output phase of a SIPOC is that we need to have an understanding of what they are because they are of interest to our customer. In addition it is important to recognise that they are lagging indicators.

Output KPIs are often easy to measure because they measure things like customer satisfaction, how many defects a customer brought back to us or if delivery to the customer occurred on time. So while they are quite easy to measure, they are after the fact, after the deal is done- the service has been delivered. So lagging indicators are great, but they only tell you what has happened, they don’t help you correct problems in the process before they get to the customer.

They are then, however, helpful in the prediction of things like customer satisfaction KPI’s. If you were to provide a service to a customer and then ask them how satisfied they were and they say it was a 7/10- you are going to ask them why. It may be something that is happening early on in the process, or even before the process, that you don’t know is happening. The lagging indicator is your last line of defence against problems you didn’t know existed. An opportunity will be identified and so you can start to do something about it, and hopefully put a leading indicator in to help monitor countermeasures to an issue.

Implementation of a SIPOC leads to an understanding of the KPIs that are critical to transforming your business processes, making the commencement of a program of change a possibility.

Reach out if you want to know more about how to create a culture of continuous environment in your workplace.

Check out our Capability Training options.

or

Book a discussion to find out how we can help your business.

Much Respect,

Daniel

Subscribe for updates

We provide free updates and advice regularly to help you improve your business and leadership skills, and for exclusive content there is a paid subscription too!

Follow us on YouTube

Our YouTube channel is a must for Leaders in business who want to empower their teams and improve their processes. You'll find plenty of our current thinking there

Build your Capability with our Members Program

We do consulting differently, in that we believe in building your capability to improve - we want to provide you with the secrets to success, not keep it all to ourselves! Our exclusive Member Program coaches you to be a great Leader, to empower your people to drive improvement, and identify large gains in employee engagement, quality and performance.

Talk to a consultant

We love to have a chat. We also like to make sure we have time just for you. You can book a chat and we can discuss your continuous improvement journey. We are happy to provide as much obligation-free advice as we can during the call, including what would be the recommended next steps for you to take.