Map your future

Looking forward, on your value stream mapping journey, I want to talk about mapping a future state.

It’s important to recognise that your business needs to have some level of a target or goal that you want it to hit.

This is the purpose of mapping a future state. It’s relatively easy to identify the waste and problems in your business, but it’s another matter to actually do something about it! Not to mention how much are you going to do- how far are you going to go?

Value stream mapping of a particular area should happen around every six months.

You can work much faster if you want to, depending on your appetite for pace, the resourcing available, demands of production and so on. But when mapping a future state and looking forward to the next goal, I would always suggest that you push yourself and push your team. Set a high, hard target. Don’t be afraid. Make sure that the wastes identified are apparent, even if they’re not going to be easy to fix: if it’s clear what needs to change, then you’ve got a much better chance of getting everybody on board.

One of the key things to establish with a future state is an understanding of takt time

This can be identified by customer demand, or some other unit of measurement. This can be quite challenging, particularly if you work in a highly customisable product or service industry. I have clients who move between working for five different customers one day, then it’s all just for one customer the next week.

In this highly variable environment, my recommendation is to find the smallest practical increment of work. It’s got to make sense and be easy to measure. Examples of units of measurement are things like revenue or a certain number of items produced. I am always trying to create one-piece flow.

If I understand my customer demand or daily demand, and therefore my takt time, I’m better able to identify what the one-piece flow is going to be. How small an increment can I practically work to?

Now one-piece flow is not an easy concept for teams to get across

I recommend participating in our workshops such as Makoto’s Paper Aeroplane Workshops, or Lego Simulations to facilitate this learning. These workshops help people grasp the idea of one-piece flow and not be scared of multiple setups or multiple changeovers, facilitating an understanding of the concept that the flow of materials and flow of people is much more important.

I quite often have businesses where their incremental work might seem practical for the factory floor, but it makes no sense to the engineering or the drafting or the procurement that happens beforehand. I like to look at increments of work that are going to work throughout the business.

So in your business’ future state consider- what’s your takt time, what’s is the unit of measure?

It needs to be something that you can measure consistently, even if it’s not perfect. Consider who else needs to be involved in the value stream. Is the value stream just in your factory or service delivery department, or does it include the departments around you? Do you need to include the planning, engineering, drafting, quotes or estimating department? Do they need to work to the same takt time? It’s surprising how much work naturally speeds up and lead times shorten if you do include the larger picture in your consideration of the value stream.

Case study

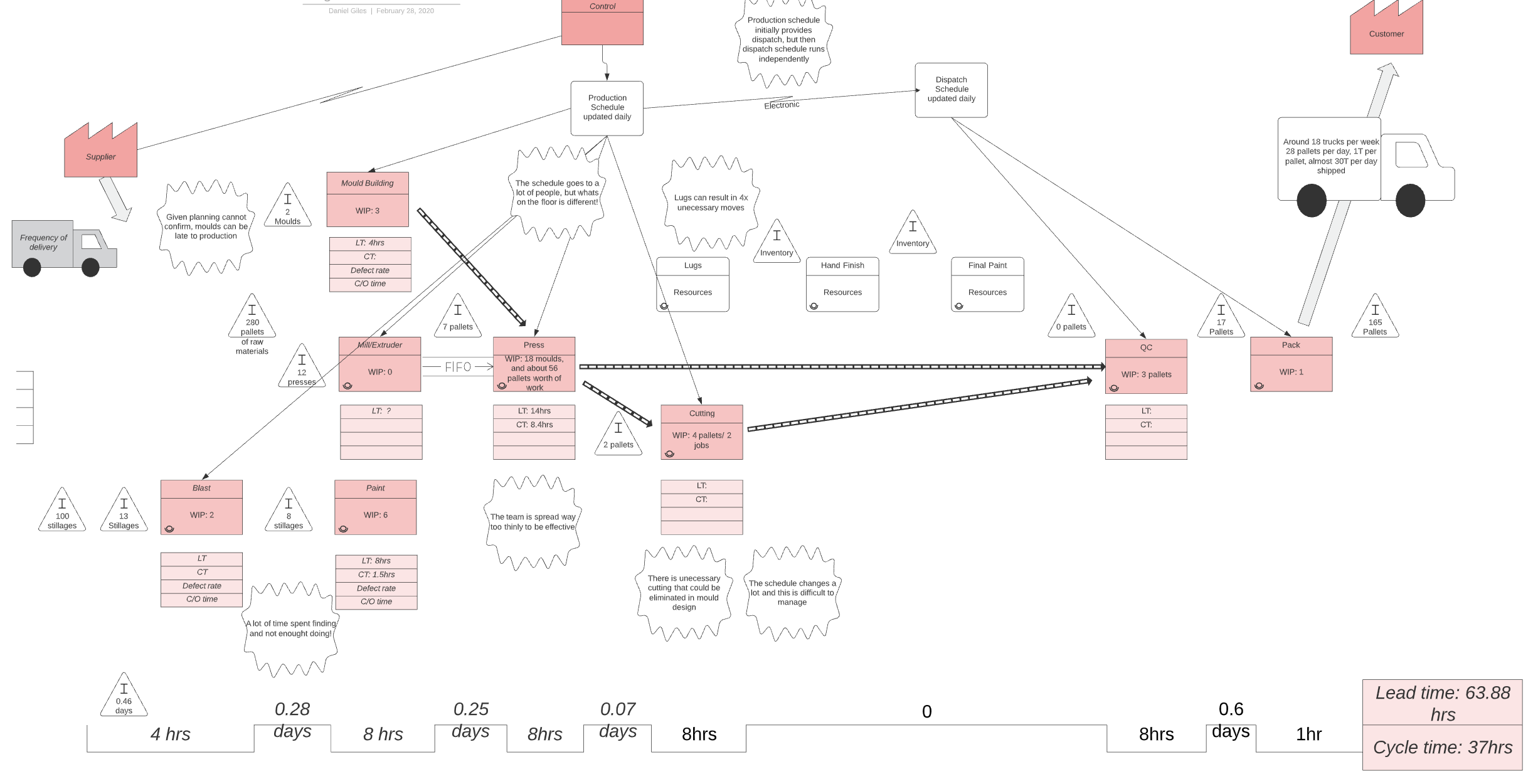

In the example current state pictured, we identified that the wastes in their process were creating a lot of work in progress.

Changes implemented

- Identification of the pacemaker in the process, allowing us to determine the takt time

- Break down of bigger jobs to smaller increments or smaller one-piece flow increments to better match takt time

- Division of the work in assembly areas

- Adherence to timeframes

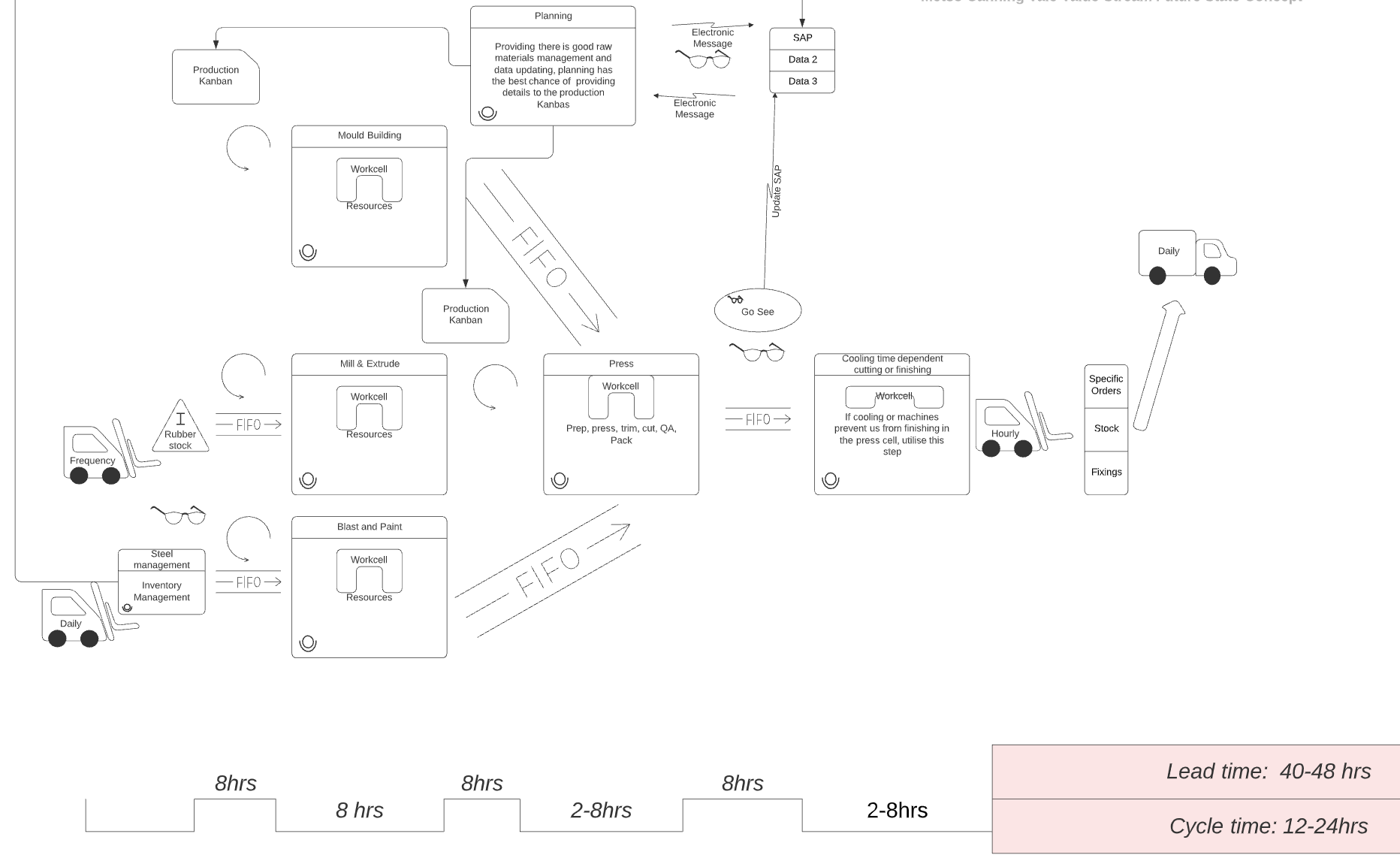

So where did we go from there? Let’s look at the future state.

Outcomes

- A very short lead time resulted

- The team evolved into one that could work together to problem-solve issues

- People’s strengths were drawn upon

- Team members supported each other

- Cross-training of people within teams, creating a flexible workforce

- A better overall attitude, a better teamwork environment, a happier team

So the changes implemented helped us to build a strong future state

And it also made the future state much more achievable within the six-month time frame. But like I’ve said before if you’ve not really done value stream mapping well or taken it to the next level, it is a really good idea to get help from someone who’s experienced. A couple of days can see your business in a completely different light and you’ll have a completely different understanding of how waste is really affecting the flow of your business.

Let us help you move to your future state. Contact us to find out how.

or

Check out our Capability Training options.

or

Book a discussion to find out how we can help your business.

Respect,

Daniel.

Subscribe for updates

We provide free updates and advice regularly to help you improve your business and leadership skills, and for exclusive content there is a paid subscription too!

Follow us on YouTube

Our YouTube channel is a must for Leaders in business who want to empower their teams and improve their processes. You'll find plenty of our current thinking there

Build your Capability with our Members Program

We do consulting differently, in that we believe in building your capability to improve - we want to provide you with the secrets to success, not keep it all to ourselves! Our exclusive Member Program coaches you to be a great Leader, to empower your people to drive improvement, and identify large gains in employee engagement, quality and performance.

Talk to a consultant

We love to have a chat. We also like to make sure we have time just for you. You can book a chat and we can discuss your continuous improvement journey. We are happy to provide as much obligation-free advice as we can during the call, including what would be the recommended next steps for you to take.