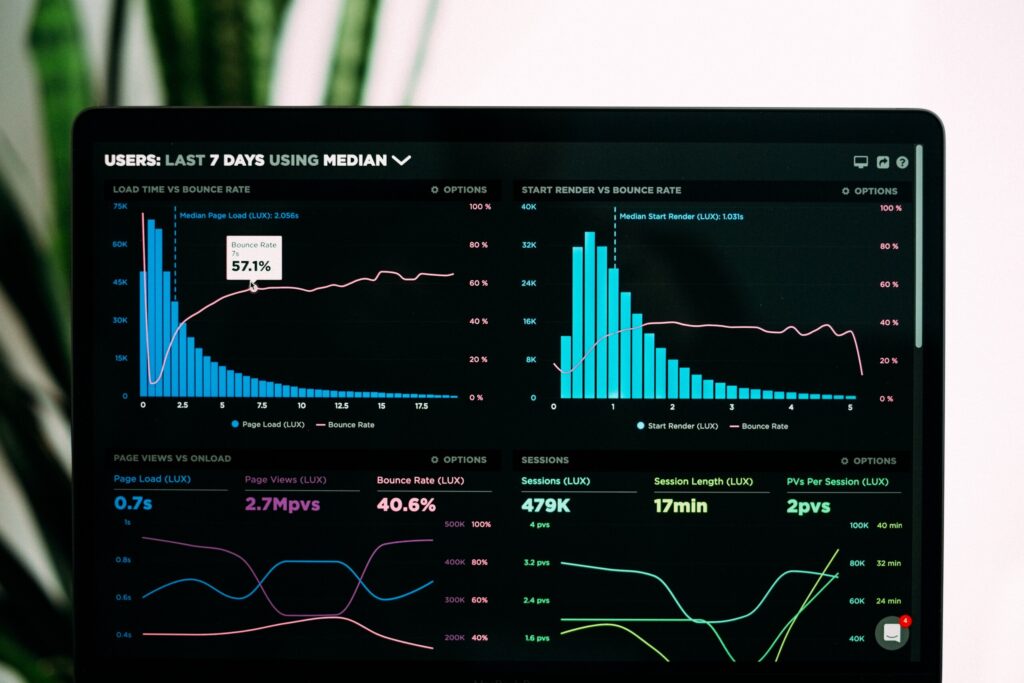

Establishing KPIs and targets for business success

In today’s competitive business environment, it is vital for organisations to establish effective performance management systems to ensure they are on track to achieve their strategic goals. KPIs and targets are essential tools for measuring and tracking your organisation’s progress toward achieving its goals. By establishing relevant KPIs and setting specific targets, businesses can…

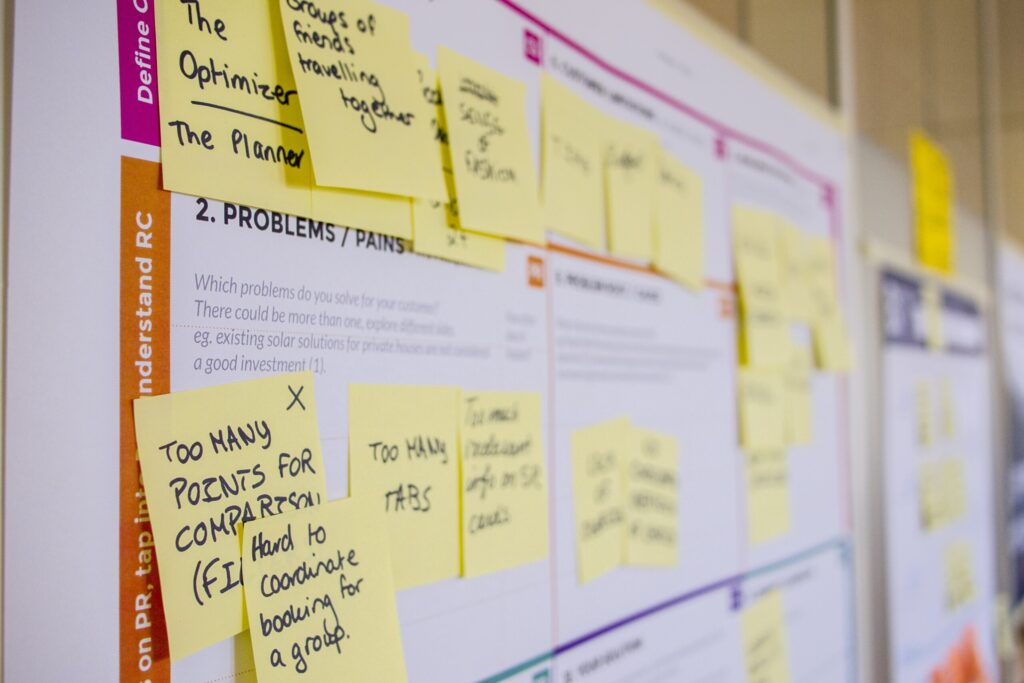

Read MoreSolving problems for long-term success

Continuous improvement and effective problem-solving are essential for organisations seeking to optimise their processes and enhance performance. A systematic approach Root Cause Analysis (RCA) is a systematic approach that helps identify the underlying causes of problems and enables teams to develop long-term solutions to prevent a recurrence. According to a study by Andersen and…

Read MoreBoosting team collaboration with daily stand-up meetings

In today’s fast-paced business environment, effective communication and collaboration are essential for a team’s success. One proven approach to fostering teamwork and ensuring projects stay on track is the implementation of daily stand-up meetings. The benefits These brief gatherings, rooted in Lean practices, have been shown to positively impact team coordination and project outcomes…

Read MoreEmbracing continuous improvement with the PDCA cycle

The Plan-Do-Check-Act is an effective framework for implementing continuous improvement within organisations. Driving continuous improvement methodologies With its focus on data-driven decision-making and iterative problem-solving, the PDCA cycle is closely related to Lean principles and can significantly enhance efficiency and performance. In this article, we will discuss the benefits of adopting the PDCA cycle…

Read MoreEnhancing business efficiency with value stream mapping

Value Stream Mapping (VSM) is a proven Lean methodology that enables organisations to visualise, analyse, and optimise their processes in pursuit of increased efficiency and reduced waste. This powerful tool offers a systematic approach to identifying inefficiencies and streamlining operations, ultimately leading to improved productivity and cost savings. Let’s explore the benefits of VSM and…

Read MoreThe key to business excellence

In the contemporary business environment, maintaining a customer-focused approach is essential for achieving and sustaining success. Aligning your organisation’s goals and vision with customer needs enables businesses to deliver value, foster customer loyalty, and maintain a competitive edge. This article discusses the importance of customer alignment in driving business excellence and offers a four-step approach…

Read MorePlanning and execution processes for business excellence

In today’s increasingly competitive business landscape, organisations must continuously seek ways to enhance their performance and maintain a competitive edge. Effective planning and execution processes are critical components of this pursuit for business excellence. Standardising and optimising these processes not only improves efficiency and reduces waste but also bolsters overall performance. This article discusses…

Read MorePractices for business excellence

In today’s competitive business environment, organisations must constantly seek ways to improve their processes and overall performance. Visual management and continuous improvement are two vital methodologies within a Lean Management System that can help organisations achieve operational excellence. This article will provide an overview of these concepts, discuss their significance in fostering a culture…

Read MoreDeveloping Leadership

Leadership coaching abilities and skills pathways are essential components in driving business excellence. By developing these competencies, organisations can better support their teams, foster employee engagement, and promote a culture of continuous learning and improvement. A study by Ellinger et al. (2011) highlights the importance of leadership coaching in enhancing employee performance and organisational…

Read MoreBoosting Team Performance

In today’s rapidly changing business environment, leaders need to be agile and adaptive to keep their teams engaged and performing at their best. One of the most powerful tools at a leader’s disposal is providing effective feedback and coaching to help team members grow and improve. According to a Gallup study, employees who receive…

Read More